- Shortcut menu

- Main menu shortcuts

- Skip to content

PRODUCT INTRODUCTION

Electrolyte

The electrolyte produced by Dongwha Electrolyte is applied in various forms and applications, such as lithium secondary batteries and lithium primary batteries (prismatic, cylindrical and polymer), and capacitors. We supply various high-performance and high-stability electrolytes to battery-related companies.

The electrolyte for lithium secondary batteries is an ion conductor that dissolves lithium salts in high-dielectric, high-viscosity, and low-viscosity organic solvents. It must have high ionic conductivity, low freezing point, appropriate concentration of lithium salt and electrochemical stability.

We are advancing toward becoming the world's best electrolyte manufacturer through various formulation applications and additive researches In order to manufacture high-performance, high-stability electrolytes.

01. Introduction

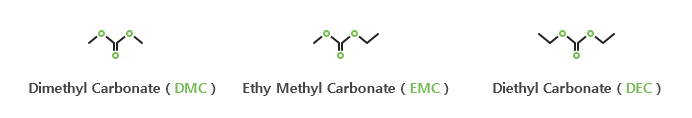

An electrolyte is produced by dissolving lithium salts such as LiPF6 in a mixture of 3 to 5 types of cyclic carbonate-based and linear carbonate-based organic solvents.

Type of organic solvent

| Cyclic Carbonate |

|---|

|

| Linear Carbonate |

|---|

|

02. Features of electrolyte

| Category | Features |

|---|---|

| High power | Low resistance / high ionic conductivity electrolyte |

| Long-life | 전극계면층 안정화 전해액 |

| High capacity | High voltage / oxidation-inhabited electrolyte / electrolyte for silicon cathode |

| High reliability | High temperature decomposition and gas generation-inhibited electrolyte / polymer electrolyte |

| High stability | Flame retardant / electrolyte with overcharge inhibitor |

03. Applications of electrolyte

Lithium-ion battery (cylindrical, square, polymer) of laptops, smartphones, and wireless home appliances, ESS, electric vehicle (xEV).

04. Features of Electrolyte Products

- · Solvent purity 99.99%↑

- · Moisture content 20ppm ↓

- · Metal ion 5ppm ↓

- · Protic Solvent content 100ppm ↓

- - Promote decomposition under high voltage (above 3.5V) and react easily with lithium metal

- - H2 generation and irreversible capacity increase due to decomposition reaction with lithium metal

- · Impurities ↓

- · Effect on resistance value after battery manufacturing

- · Influence on quality stability of electrolyte

- · Causes battery performance variation

05. Electrolyte specification

| Test Item | Unit | Specification | Actual Data | Test Method |

|---|---|---|---|---|

| Moisture | ppm | 20 Max. | 10 Max. | Karl-Fischer |

| Acid as HF | ppm | 50 Max. | 30 Max. | Titration |

| Chloride Content | ppm | 5 Max. | 1 Max. | Turbidimetry |

| Sulfate Content | ppm | 10 Max. | 1 Max. | Turbidimetry |

| Alkaline Metal | ppm | 5 Max. | 1 Max. | ICP-MS |

| Heavy Metal | ppm | 5 Max. | 1 Max. | ICP-MS |

06. Core competency

- · Leading company for electrolyte for lithium secondary batteries

- - 53,000 tonnes/year production capacity

- - Own supply chain of core additives for xEV

- · Building a global business infrastructure

- - Own production sites in four countries(Korea, China, Malaysia, Hungary)

- - Global raw material supply and demand channels (LiPF6 strategic partners)

- · Accumulated development capability

- - 112 patents (80 domestic and 32 overseas)

- - Excellent manpower in electrolyte field

- - Established a joint development system with affiliates and major additive companies

- · Provide Best Solution

- - Possesses full-cell test equipment (co-development and evaluation with customers)

- - Fast response to customer needs and maintain long-term partnership

- - Joint development of next-generation models with major xEV battery makers